PLASTIMAGEN MEXICO 2025

Date: 11-14 March 2025

Location:Mexico City / Exhibition Centro Citibanamex

Booth No:173

Saudi Print & Pack 2024

Date : May. 06 – 9th, 2024

Location : Riyadh International Convention & Exhibition Center Riyadh

Booth : 1A-208

NPE 2024

Date : May. 06 – 10th, 2024

Location : Orange County Convention Center

Booth : S30115A

The 18th Vietnam International Plastics & Rubber Industry Exhibition 2018

Exhibition date: 10/4/2018 (Thursday) - 10/7/2018 (Sunday)

Exhibition time: 09:00 ~ 17:00

Exhibition location: Saigon International Exhibition and Convention Center

Booth number: 772

The 12th IRAN PLAST 2018

Exhibition date: 09/24/2018 (Monday) - 09/27/2018 (Thursday)

Exhibition location: Tehran International Exhibition Center

Booth No.: H40-41A

The 16th Taipei International Plastics and Rubber Industry Exhibition 2018

Exhibition date: 08/15-08/19, 2018

Exhibition time: 10:00 ~ 18:00

Exhibition location: Taipei Nangang Exhibition Center Hall 1

Booth number: L203

PLASTAR in K-show 2022

Date : Oct. 19 – 26th, 2022

Location : Düsseldorf, Germany

Booth : 16A70

_pic.jpg)

PLASTAR is the leading brand in the plastic machinery industry

PLASTAR a 20-year brand,belongs to the industry and trade of plastic machine manufacturers.Established in 2008, Wenzhou Aoxiang Packaging Machinery Co., Ltd. is a scientific and technological enterprise specializing in the production and operation of plastic packaging machinery. In 2020, the company opened a branch in Hangzhou,Zhejiang Pengxiang fine machinery Manufacturing Co., LTD., the company's environment is particularly good, the company is headquartered in China's packaging machinery city, Wenzhou City, Zhejiang Province, Wenchenng County.

Chinaplas2025 International Rubber and Plastic Exhibition, Innovative Technology Leading the New Benchmark of Film Manufacturing!!

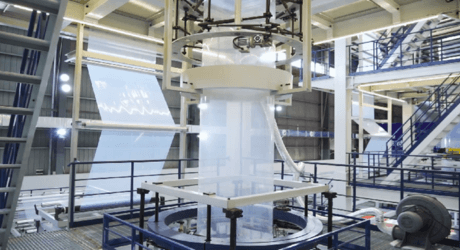

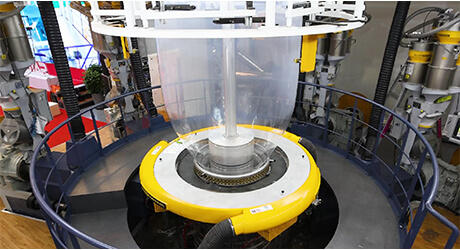

At the just concluded Chinaplas International Rubber and Plastic Exhibition, our independently developed five layer co extrusion blown film machine became the focus with breakthrough technology. At the exhibition site, Manager Chen was interviewed by the organizer to deeply analyze how equipment can promote the upgrading of thin film manufacturing through innovative processes.

Blown Film Machine——Ultimate Guide

As the name implies, a film blowing machine is a machine for blowing film. It is a plastic production machine. There are many types of film blowing machines, including PE, PC, PVC, etc. Different types of films can be blown into different types by adding different types of particles. It can be made into greenhouse films, food packaging bags, express bags and other different products.

Shrink Film Blowing Machine

Shrink film blowing machines play a critical role in modern packaging industries. These machines primarily use LDPE, a material known for its flexibility, strength, and transparency, to produce high-quality shrink films. By catering to diverse packaging needs, from food preservation to industrial goods transportation, they enable cost-efficient and protective solutions.

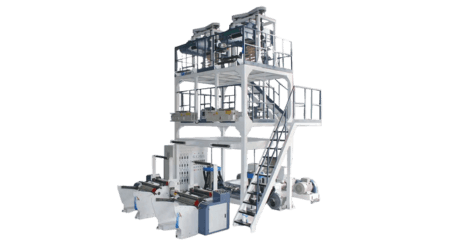

Multilayer Blown Film Machine

Multi-layer co-extrusion film blowing machine can produce higher-level and complex plastic films. Due to its multi-layer structure, it has better physical and chemical properties and is suitable for producing difficult plastic films, such as packaging films with high waterproof, high transparency, high strength and other requirements.

HDPE Blown Film Machine

HDPE Blown Film Machine:Shaping excellent films and leading the future of the industry

Co-Extruded Film: A Deep Dive into Its Properties and Use Cases

Co extrusion blown film, also known as co-extruded film, is a special plastic packaging material. It combines the unique properties of each layer of material by simultaneously melt-blending multiple polymers during the blown film extrusion process to form a single multi-layer structure.

Agricultural Blown Film Machines : Revolutionizing Farming with Advanced Film Technology

Agricultural blown film machines play a crucial role in modern farming technology, providing versatile solutions for various agricultural applications. From mulching and greenhouse covering to silage wrapping, these specialized machines ensure efficient and cost-effective agricultural film production tailored to the needs of the agricultural sector. In this comprehensive blog, we will explore the key features, materials, working principles, benefits, advancements, and tips for choosing the right agricultural blown film machine.

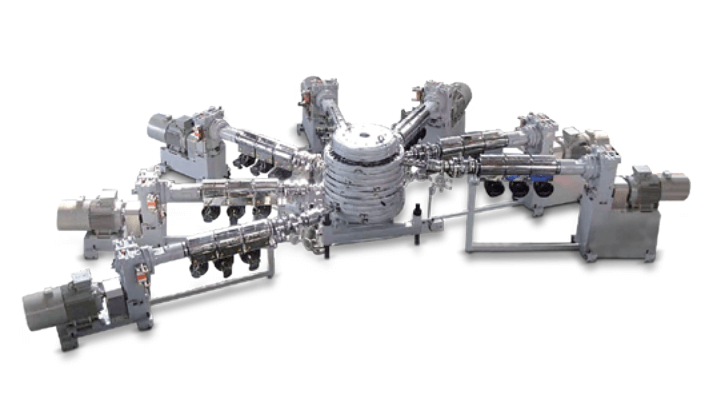

12 Essential Components of Blown Film Line: A Comprehensive Guide

Blown Film Extrusion Lines are the powerhouses behind various thin plastic films used in packaging, agriculture, construction, and more. Understanding their parts is crucial for optimal production, consistent quality, and efficient troubleshooting. Let's explore the 12 key components involved in this fascinating process.

_pic_pic.png)

Five-layer POD Film Blowing Machine: Leading the Trend in Film Innovation and Application Value

With the continuous development and technological advancement of the packaging industry, film manufacturing processes are also constantly evolving to cope with the increasingfunctional and environmentally friendly demands for flexiblepackaging materials in the downstream market.

LDPE Blown Film Machine - All You Need to Know

Explore LDPE film production through the sophisticated features of LDPE Blown Film Extrusion Machines. Specifically designed for thin plastic films and bags, these machines transform LDPE resin into a blown tube, which is stretched, cooled, and refined through precision slitting and winding. LDPE resin, known for unmatched flexibility, strength, and moisture barrier properties, takes center stage in manufacturing plastic bags and packaging films, outshining alternatives like HDPE and LLDPE. LDPE films set a new standard with enhanced clarity and gloss, revolutionizing plastic film production.

5/7/9-Layer Blown Film Extrusion Lines for Barrier Film : The Ideal Choice for Food Packaging

In the race to stay ultra-competitive in today's dynamic food industry marketplace, it is important to invest in the right technology that marries functionality, durability, and quality. Enter the 5/7/9-layer blown film extrusion lines — the epitome of cutting-edge technology in the world of film packaging, particularly suited for accommodating a wide range of food packaging applications with their superior barrier properties, strength, and printability.

Improve the Competitiveness of Plastic Film Extrusion Machine

We have a machine with two sets of extrusion parts and a three-layer co-extrusion die. The surface layer shares one extruder, which we call Layer A, and the other extruder is on the middle layer, which we call Layer B. Therefore, the blown film structure is a three-layer co-extruded film of A, B, and A layers.

Three Structures of a Blown Film Machine

The blown film machine is suitable for producing various kinds of high-end packaging films with sound barrier properties, freshness retention, moisture retention, freeze resistance, oxygen resistance, and oil resistance. It can be used for the light and heaving packaging of fresh fruits, meat products, pickles, milk, liquid beverages, and medicine.

Advantages of Multi-Layer Co-Extrusion

In order to meet customers’ special requirements for the production process and co-extrude multi-functional plastic films that combine the properties of various materials (such as breathability, waterproofness, insulation, toughness, etc.), we have developed the multi-layer co-extrusion plastic blown film machine after years of research and practical development. Its purpose is to give play to the advantages of different materials and avoid the shortcomings of a single material or a single-layer blown film machine. PLASTAR is committed to providing customers with market-competitive blown film machines.

Jordan, three-layer 1600 film blowing machine, which is subsequently used for printing and lamination to produce various types of flexible packaging.

Explore how PLASTAR's sustainable 3 layer blown film machine supported a Jordanian packaging company in boosting efficiency, reducing waste, and embracing eco-friendly practices to deliver innovative flexible packaging solutions.

Vietnam, ABA2000 film blowing machine, pearl cotton composite film, etc.

A Vietnamese packaging solutions manufacturer partners with PLASTAR, utilizing the ABA film blowing machine to manufacture pearl cotton composite films, enhancing product quality and promoting eco-friendly packaging solutions.

Bulgaria, three-layer 1200 film blowing machine, composite film, various food industry flexible packaging, etc.

A Bulgarian company's investment in PLASTAR's three-layer blown film machine leads to innovative multi-layer films with enhanced barrier properties, transforming food packaging solutions.

Bulgaria's Leading LDPE Bag Manufacturer Upgrades to ABA1000 Film Blowing Machine for Enhanced Quality and Efficiency

A Bulgarian LDPE bag manufacturer upgraded to PLASTAR's ABA film blowing machine, resulting in a 30% production boost and films with enhanced strength, transparency, and consistency, meeting customer demands effectively.

Brazilian Manufacturing Industry Adopts Monolayer 1200 Film Blowing Machine to Boost LDPE Packaging Capacity

PLASTAR's monolayer blown film machine installation in Brazil elevates LDPE film production, catering to the increasing needs of food packaging, industrial sectors, and consumer goods.

Revolutionary Blown Film Machines in Saudi Arabia for Diaper and Tissue Outer Packaging

Learn how PLASTAR's cutting-edge blown film machines empowered a Saudi firm to expand its production of high-quality films for diaper and tissue packaging, ensuring superior performance and sustainability.

Efficient Black Geomembrane Film Manufacturing: Single-Layer 2000 Film Blowing Machine in El Salvador

Read about the successful deployment of PLASTAR's monolayer blown film machine in El Salvador, enabling high-quality black geomembrane film production for infrastructure projects.

5-Layer 1800 Blown Film Machine: Meeting Vietnam's Packaging Industry Needs

Read about PLASTAR's collaboration with a leading Vietnamese manufacturer, installing a 5-layer blown film machine to advance composite film production for various packaging applications, ensuring higher strength and barrier properties.

Dominican Republic Adopts Advanced Blown Film Machines for Composite Film, Shrink Film, and Bags

PLASTAR supplies three specialized film blowing machines to a Dominican packaging company, enabling the production of high-quality laminated films, shrink films, and various plastic bags, supporting expansion into new Caribbean markets.

South Africa: Two Blown Film Machines Empower Shrink and Lamination Film Production

Learn how a South African packaging company boosted its market position by partnering with PLASTAR, implementing state-of-the-art blown film lines to produce superior shrink and lamination films with flexibility and precision.

Lebanon Company Adopts 3 Layer Blown Film Machine to Meet Growing Demand for Composite Films

Explore PLASTAR's role in assisting Lebanon's packaging leader to upgrade from single-layer to three-layer blown film technology, achieving stable, high-quality composite film production.

Ukrainian Packaging Company Upgrades to 3-Layer Blown Film Machine for High-Quality Shrink Film Production

PLASTAR's innovative three-layer blown film technology enables a Ukrainian company to meet rising demand for high-quality shrink films, enhancing product range and efficiency.

Mongolia Company Boosts Efficiency in Shrink Film Production with ABC Blown Film Machine

Mongolia Packaging Company selected PLASTAR's three-layer blown film machine to enhance shrink film production, achieving higher efficiency and superior quality to meet the increasing market demand.

Saudi Arabia Company Adopts Two-Layer Blown Film Machine for Garbage Bag Production

Learn how a Saudi plastic manufacturer upgraded their trash bag production by partnering with PLASTAR to install a tailored double-layer AB-1700 film blowing machine, boosting efficiency and meeting growing customer demand.

Jiangxi, China - ABA Three-layer Co-extrusion Blown Film Machine

The customer is a local small- and medium-sized blown film manufacturer in Jiangxi which was established in 2018.

Jiangsu, China - Three-layer Co-extrusion Self-adhesive Film Machine

Wuxi XX Adhesive Tape Co., Ltd. was established in Huishan District, Wuxi City in 2002. Its business scope includes the manufacturing of PE protective films, adhesive tapes, general equipment and accessories.

Philippine - ABA Three-layer Co-extrusion Blown Film Machine

In 2018, a Philippine customer visited our factory and established trust and cooperation relationship with us.

Jordan - ABC Three-layer Co-extrusion Blown Film Machine

The customer from Jordan met with us in CHINAPLAS in 2018 and was convinced by our product(ABC three-layer co-extrusion blown film machine: 1800 mm) quality and service.

Kenya - ABC Three-layer Co-extrusion Blown Film Machine

At the end of 2018, a Kenyan customer purchased an ABC-1800 series: ABC three-layer co-extrusion blown film machine through an Indian middleman, which was mainly used to produce bags and shrink films.

Slovakia, Russia - Two-layer Stretch Film Extrusion Machine

In 2017, a Russian customer found us through social media and successfully ordered a two-layer stretch film extrusion machine: CF-2L1000.

Ukraine - Mini PE Film Blowing Machine

In the Guangzhou exhibition in 2019, a Ukrainian customer was impressed by our equipment at first glimpse and trusted in our strength, then he signed a contract on the spot to buy equipment for the plastic film extrusion machine.

Vietnam - High-speed ABA Three-layer Co-extrusion Blown Film Machine

In the Vietnam International Plastics & Rubber Industry Exhibition: VietnamPlas 2017, we exhibited two blown film extrusion machines that deeply attracted many customers and was finally ordered on the spot during the exhibition.

South Africa - ABC Three-layer Co-extrusion Blown Film Machine

In 2019, A South African customer purchased a three-layer co-extrusion blown film machine: ABC-1700 series that is mainly used to produce bags.

Indonesia - Mono-layer 3000-mm Blown Film Extrusion Machine

In 2017, an Indonesian customer saw our equipment at the exhibition, and later visited our factory to negotiate on cooperation.

Argentina - Single-layer Blown Film Extrusion Machine

In February 2018, An Argentina customer bought three SD-50 single-layer 600mm HDPE blown film machines.

Bolivia - Single-layer LDPE Blown Film Extrusion Machine

In October 2018, a Bolivian customer purchased two single-layer LDPE blown film extrusion machines.

Vietnam - Five-layer Co-extrusion Blown Film Machine

In October 2019, a Vietnamese customer successfully installed the 1600 mm ABCDE five-layer co-extrusion blown film machine.

Turkey - Plastic Film Extrusion Machine

In the exhibition of 2017, a Turkish intermediary customer chose us amidst many competing suppliers and successfully purchased the 2017 version of Asda equipment of the plastic film extrusion machine.

Panama - Single-layer Blown Film Extrusion Machine

At the end of 2018, a customer successfully purchased the single-layer blown film extrusion machine SD-55-700, and the machine has been operating well in the customer’s factory.

Iran - ABA Three-layer Co-extrusion Blown Film Machine

In October 2017, an Iranian customer bought the ABA three-layer co-extrusion blown film machine: ABA-1200.

Guangzhou, China - 7-layer Co-extrusion Blown Film Machine

The customers is a large-scale blown film manufacturer in Shenzhen, Guangdong that was incorporated in 2016 and specializes in the manufacturing of plastic protective films;

What Products are Made by Blown Film Extrusion Line?

Blown film extrusion lines produce LDPE, LLDPE, HDPE, EVA films, barrier films, and shrink films for various applications.

What is the 7-layer Blown Film Extrusion Line?

The 7-layer blown film extrusion machine is ideal for producing high-quality multi-layer plastic films for various industries, offering specific functionalities and properties.

What are the benefits of the 7/9/11 layer blown film extrusion line over the 3/5 layer?

PLASTAR offers 7, 9, and 11-layer blown film extrusion lines, providing superior quality, production efficiency, customizability, and sustainability benefits. Gain a competitive edge in your industry.

What blown film extrusion line is recommended for PE shrink film?

Choose the right blown film extrusion line for PE shrink film production, such as the ABC Model, to ensure efficiency, quality, and cost-effectiveness.

What is mono-layer blown film extrusion machine?

Learn about Mono-Layer Blown Film Extrusion Machine, its components, and advantages including high productivity, excellent clarity, and consistent quality.

What is the Manufacturing Process of Blown Film Extrusion?

Blown film extrusion is a popular method for producing plastic film products used in a variety of industries. This article explains the process of blown film extrusion and its benefits.

Advantages of 3 Different Screw Surface Treatments for Blown Film Extruders

Surface treatment of screw and barrel components improves blown film extruder efficiency and performance. Coatings, platings, and polishing enhance wear resistance and durability.

Difference between ABA and ABC Blown Film Extrusion Lines

ABA and ABC blown film extrusion lines differ in layer arrangement and extrusion process. ABA films provide strength, while ABC films offer high performance for demanding applications.

What is the Difference between Extrusion and Injection Molding?

Extrusion and injection molding are plastic manufacturing processes with differences in principle, product shape, tooling, volume, and material selection. Both have advantages depending on the specific application.

Blown Film Extrusion Troubleshooting Guide

To troubleshoot blown film extruders, follow the 7 steps of the systematic approach, and that need Technical experience, and process understanding are required.

What are the Raw Materials Used in a Blown Film Machine?

Blown film machines produce plastic films for packaging and wrapping. Common raw materials include PE, PP, PVC, EVA, PA, and PS. Additives may enhance properties.

What is the Price of Blown Film Extrusion Line?

Blown film extrusion lines vary in price based on features and capacity, ranging from $20k-$30k to millions. Consider total cost and needs before purchasing. Plastar Machinery offers quality, customizable options at competitive prices. Contact for more info.